I-Pneumatic Actuator yeValve yolawulo oluzenzekelayo

Iimpawu zeMveliso

1. Iimpawu

Isalathisi semisebenzi emininzi kunye ne-NAMUR yokufakela i-slot esemgangathweni inokufakela ngokulula izixhobo ezahlukeneyo, ezifana ne-valve positioner, switch limit limit, njl.

2. Umgca wemveliso

I-shaft ephumayo ye-high precision edibeneyo edibeneyo yenziwe nge-nickel-plated alloy steel, ehlangabezana nemigangatho ye-ISO5211, i-DIN3337 kunye ne-NAMUR.Iyakwazi ukulungelelaniswa ngokweemfuno zomsebenzisi, kwaye inomgangatho wensimbi engenasici yokukhethwa.

3. Ibhloko yesilinda

I-STM6005 ibhloko yesilinda ye-aluminium ekhutshiweyo inokunyangwa nge-oxidation enzima, i-epoxy resin yokutshiza i-PTFE yokwambathisa okanye i-nickel plating ngokweemfuno ezahlukeneyo.

4. Isiphelo se-cap

Isiphelo somphetho senziwe nge-alloy ye-aluminium ye-die-cast, efakwe nge-polyester.Ukutshiza ngomgubo wesinyithi, i-PTFE yokwambathisa okanye i-nickel plating iyakhethwa.Umbala wesiciko sesiphelo matte mnyama ngokungagqibekanga.Ubume kunye nombala unokwenziwa ngokweemfuno zomsebenzisi.

5. Iipistons

Irekhi yepiston ephindwe kabini iphathwa nge-aluminiyam eyi-oxidation eqinileyo okanye intsimbi ekhandisiweyo.Indawo yokufakela i-symmetrical, isenzo sikhawuleza, ubomi benkonzo bude, kwaye isalathiso sokujikeleza sinokutshintshwa ngokulula ngokuguqula ipiston.

6. Uhlengahlengiso lokuhamba

I-screw yangaphandle emibini ezimeleyo yokulungelelanisa i-stroke inokulungelelanisa ngokufanelekileyo kunye ngokuchanekileyo indawo yokuvula kunye nokuvala kumacala amabini.

7. Imithombo yoMsebenzi oPhezulu

Imithombo ehlanganisiweyo yokupakishwa kwangaphambili yenziwe ngezinto ezikumgangatho ophezulu, ezigqunywe kwaye zicinezelwe kwangaphambili.Inokumelana ne-corrosion enamandla kunye nobomi benkonzo ende.I-actuator ebambeleyo enye inokuchithwa ngokukhuselekileyo kwaye ngokulula, kwaye uluhlu oluphumayo lwamaxesha ahlukeneyo lunokwaneliswa ngokutshintsha inani lemithombo.

8. Iibheringi kunye neepleyiti zesikhokelo

Ukungqubuzana okuphantsi kunye nezinto ezidibeneyo zobomi obude zisetyenziselwa ukuphepha ukudibanisa ngokuthe ngqo phakathi kwesinyithi kunye nesinyithi, kwaye ukugcinwa kunye nokutshintshwa kulula kwaye kulula.

9. Ukutywinwa

Izitywina ze-O-ring zenziwe nge-NBR kwiqondo lokushisa kunye ne-fluororubber okanye irabha ye-silicone kwiqondo lokushisa eliphezulu okanye eliphantsi.

Iiparamitha zobuGcisa

1. Uluhlu loxinzelelo: Max.Uxinzelelo lokusebenza 10bar

2. Uxinzelelo lomoya: 2.5bar ~ 8bar

3. Uluhlu loLungiso: 90 ° ± 5 °

4. Ubushushu be-Ambient: -20 ~ +90° C

5. Uhlobo: Ukwenza kabini, ukwenza into enye (ukubuya kwentwasahlobo)

6. Izixhobo ezikhethiweyo: I-valve ye-Solenoid, ukutshintshwa komda, indawo yombane, umlawuli womoya

7. Ukuthambisa: Zonke iindawo ezihambayo zigqunywe ngezithambiso, zandisa ubomi bazo benkonzo

8. Ixesha loBomi: Ixesha lesigidi esinye

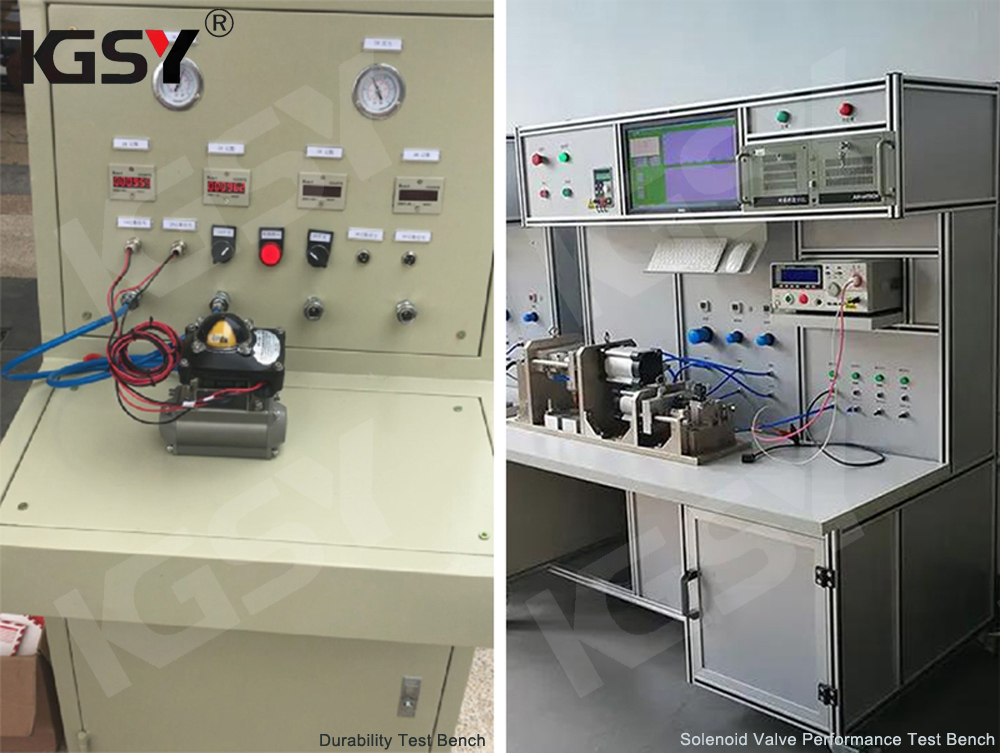

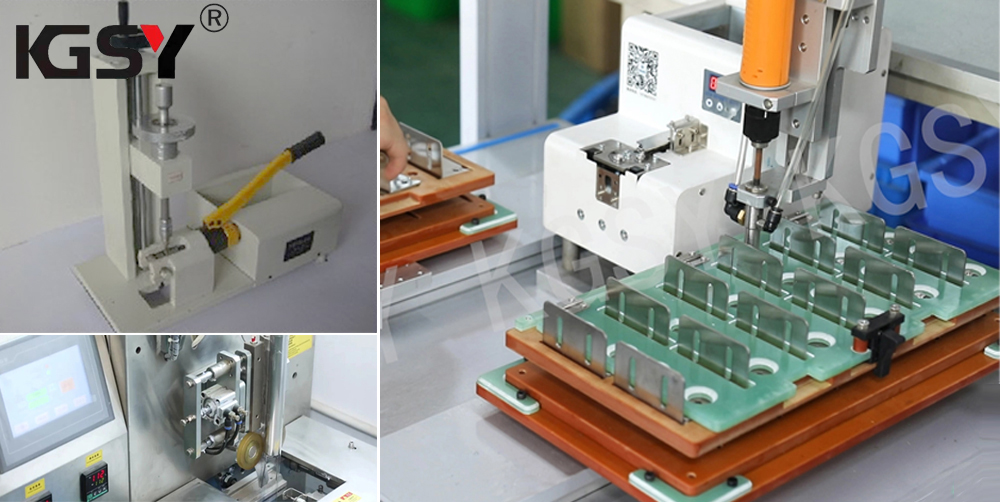

Iziqinisekiso

Imbonakalo yethu yeFactory

Iworkshop yethu

Izixhobo zethu zokulawula umgangatho